Cutting metal is not new. Metals have formed the base of a lot of our manufacturing processes for long now, and this material is not going anywhere anytime soon. With improved manufacturing standards and the demand for more precision-cut parts, though, the use of specialized tools like the metal laser cutting machine have fast become the order of the day.

In this piece, we explore some of the many fields where a metal laser cutting machine will find its feet.

Construction

The construction industry has been the biggest user of metal for a long time. Even though we are now seeing shifts to other synthesized materials like glass, acrylic and polymerized substances, that takes nothing away from the fact that metal will always have a place.

This could be in the construction of residential/ commercial buildings, the development of railways, etc. When the project is on a large scale and metal is needed, there will also be the need to save time and speed up the process.

This is just one of the places where the use of a metal laser cutting machine will fit the narrative.

Transportation

Need we say more?

There is rarely any form of transportation where metals are not in play. The cars on the road have metallic frames to them, and the same can be said of the planes that ply the air. Ships, boats, and trains are not left out of the equation either.

This shows how metal is a huge need for those in this industry.

On the back of that, growth in this field has seen the design of highly sophisticated transportation equipment. They are not only miles ahead of the ones that came before them in terms of speed and quality, but they have also been greatly advanced in terms of design.

This design, starting from the shell, won’t be possible without the use of high precision equipment like the laser cutters.

Manufacturing

There are a lot of manufacturing arms where metals laser cutting tech is in play. We are not even going to talk about construction items or parts for cars and other modes of transport anymore.

How about we look into specialized equipment, high-grade weaponry, heavy machinery, and others?

These need the kind of structure and strength that they can get from metals if they do what they do. To ensure production on a large scale that meets various standards of quality, it is also important to have a high-quality metal laser cutting machine installed.

And More

Besides the time savings from not having to manually cut the metal sheets at all times, why are these laser equipment a good fit for these fields?

For one, they help to ensure the tasks can also be less labor-intensive. It would take many hands to cut up through sheets for a large job, and that can be reduced when there is a faster piece of equipment to allow just a handful of operators to get the same job done.

Likewise, it makes the final work neater and better adherent to quality standards. This is all that a manufacturer/ constructor worth their salt would want from their creations anyway.

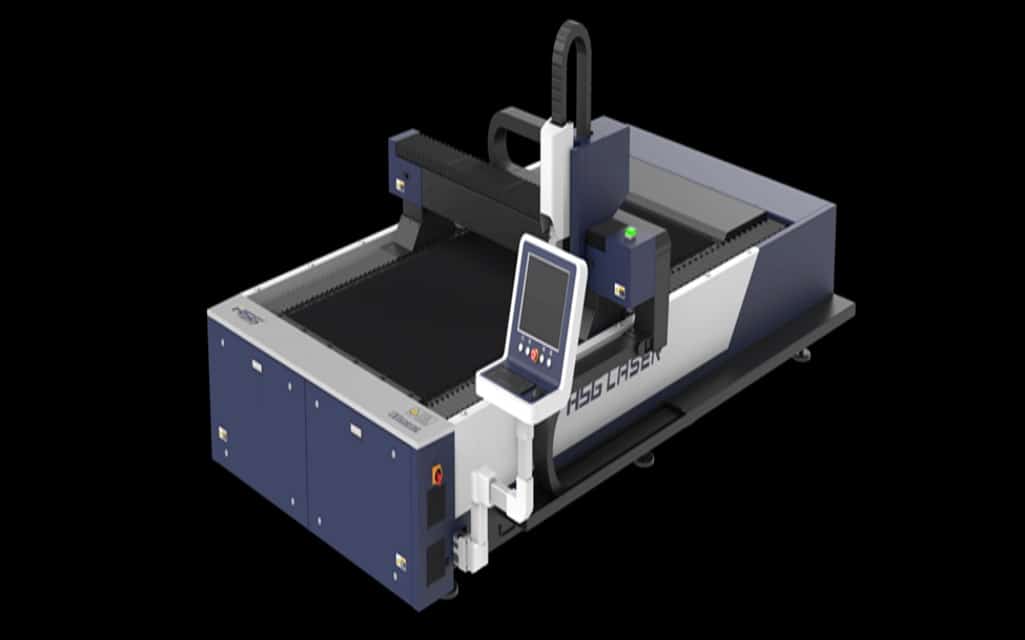

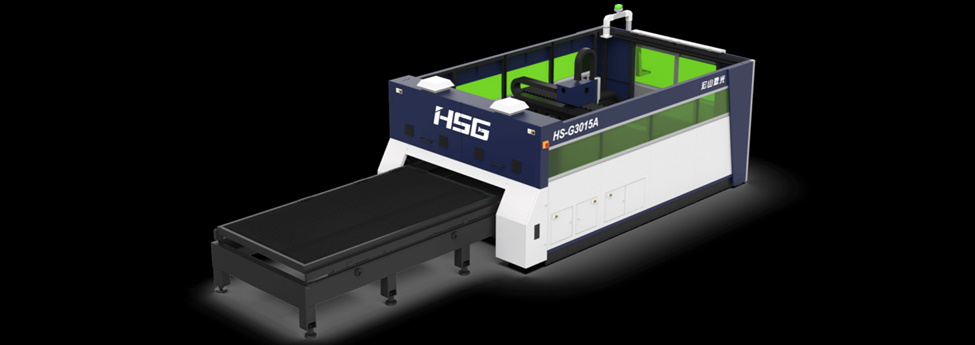

This is why brands like HSG Laser has dedicated its resources and expertise to develop the best range of metal sheet laser cutting machines for diverse users in the metal business. The machine body of the metal sheet laser cutting machine is welded with carbon dioxide, which ensures its service life of more than 20 years. Because of its compact size and high cost-effective, metal sheet laser cutting machines of HSG is favored by small to medium-sized enterprises.