If you are looking for more efficiency in your cleaning processes, there is one particularly popular method which more businesses in different industries are benefiting from, and this method certainly has a lot of merits. Ultrasonic cleaning has already been used for over seven decades in industries such as the automotive sector, but other industries have made use of it as well – and this includes the health and medical industry, the jewellery sector, the manufacturing sector, the food industry, and a lot more. But what makes ultrasonic cleaning so great, and why does this technology stand out? Here’s all you should know about ultrasonic cleaning and why you should take advantage of it: your top questions answered.

What is it?

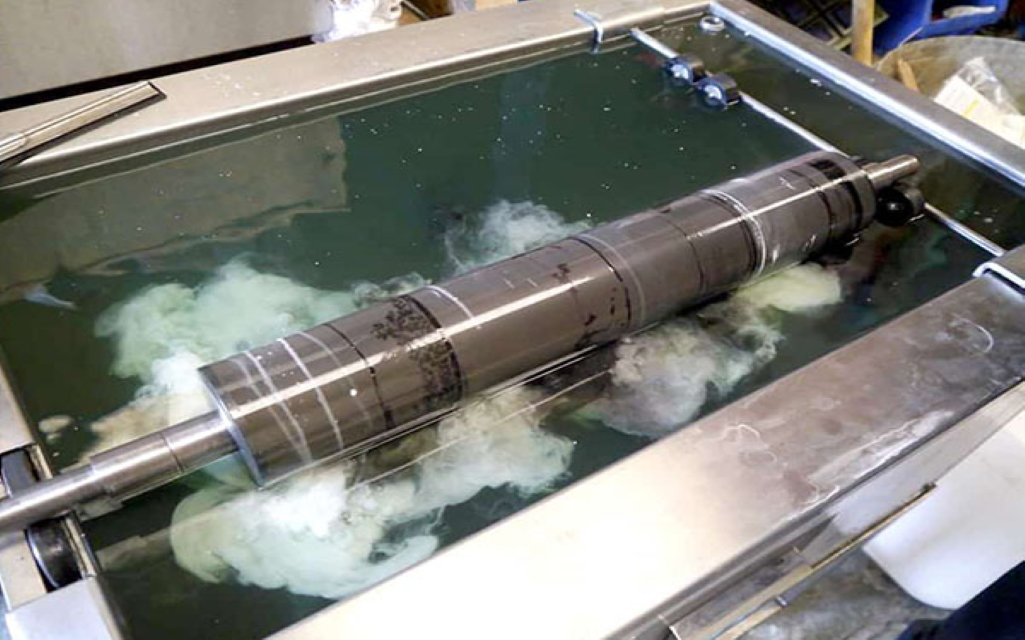

Ultrasonic cleaning makes use of machines that utilise high-frequency sound waves to quickly and efficiently remove even the smallest and toughest contaminants from the surfaces and insides of parts and components made from glass, ceramics, rubber, metal, and plastic. With ultrasonic cleaning, you can have trace amounts of dirt, and other contaminants removed even if they are well-hidden or even if they are already embedded in a solid surface. Due to this, you don’t need to disassemble any parts prior to cleaning, which saves you time as well as hassle. Ultrasonic cleaning can remove everything from dirt to rust, soot, limescale, wax, fungus and algae, carbon deposits, pigments, soil, polishing compounds, grease, and even bacteria.

The true benefits of ultrasonic cleaning

- You can tailor your ultrasonic cleaner to fit your unique and particular needs. In other words, you can have ultrasonic cleaners designed and made to address and clean a wide range of components, no matter how big they are, how small, or how fragile or delicate. Since the cleaning process is water-based, it is gentle and can be used on different objects. You can have tanks made in different sizes, and a typical ultrasonic cleaner will also be made of stainless steel, and this makes it more durable as well.

- With ultrasonic cleaning, you can also take advantage of cost-efficiency, not only in the short-term but, more importantly, in the long-term, as confirmed by the ultrasonic cleaning specialists from www.sonicsolutionsltd.com. Ultrasonic cleaning is capable of cleaning a variety of items all at the same time, and this can be quite beneficial for any business, from a medical clinic to a restaurant, manufacturing plant or factory. Ultrasonic cleaning makes use of an automated process, which makes it incredibly efficient – you don’t need a whole plethora of staff to clean a multitude of parts; all you need is one employee to load as well as unload the components or parts from the machine. As a matter of fact, you can clean as many as 20 different parts or components at any given time.

- Ultrasonic cleaning is undoubtedly friendly to the environment and doesn’t result in any harsh scrubbing; it is not abrasive, which means that you can have the most delicate parts cleaned without worrying about whether or not they can handle the cleaning process. And since it is water-based, you don’t have to worry about using chemicals with your cleaning process. A lot of companies have already reduced their use of harmful solvents just because of ultrasonic cleaning.