With 30 years of experience in the crane industry, I understand that purchasing an overhead crane is not only a significant decision but also a thoughtful investment. In this guide, I will share the knowledge I have accumulated over the years, providing you with comprehensive and valuable considerations for buying a bridge crane.

Clarify Your Needs and Usage

Before purchasing an overhead crane, it is crucial to clearly define your needs and usage. Consider factors such as your work environment, power supply, range of use, the weight and size of the objects to be lifted, lifting height, span, working speed, and frequency of operation. Choose an overhead crane that meets the required working level for your specific application.

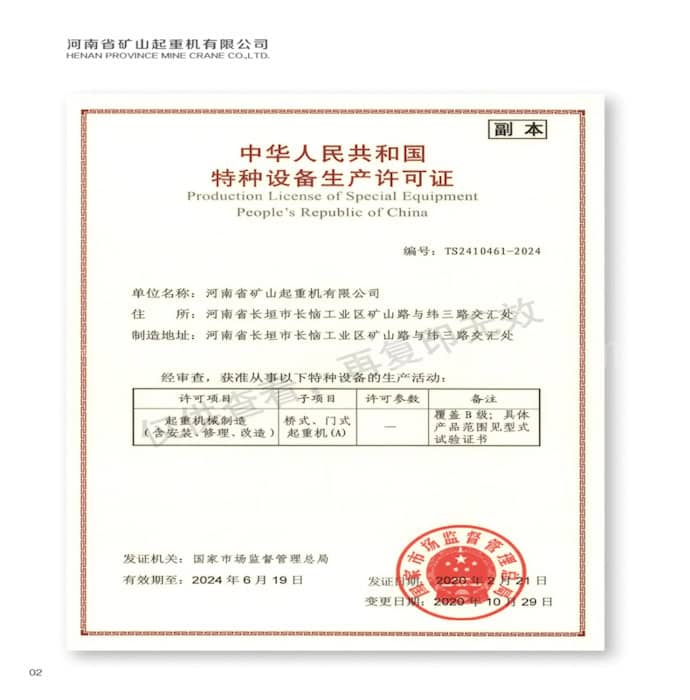

Investigate Overhead Crane Suppliers

It is essential to select a professional crane manufacturer that possesses a special equipment safety license. Investigate the compatibility of the manufacturer’s processing equipment, the standardization of their production, and the advancement of their products. If necessary, you can visit the factory in person or hire a local representative to conduct the visit on your behalf.

Communicate Crane Selection with Crane Suppliers Early

There are numerous crane models, each suited to different usage scenarios, making the selection process particularly important. Communicate with crane suppliers about the selection as early as possible, preferably during the initial stages of plant design. Early involvement of overhead crane manufacturers in integrating crane and plant drawings can help control the height of the plant effectively and prevent unnecessary investment.

For example, in a real case, a company had a large main workshop designed with two layers of cranes: a 10-ton overhead crane on the lower level and a 75-ton overhead crane on the upper level. The lower overhead crane needed to ensure an 8-meter lifting height. If the overhead cranes were matched after the workshop was built, they would typically use an LD type overhead crane. However, since the crane manufacturer was involved early in the plant design, they recommended an LDP type overhead crane instead. The LDP type overhead crane, while maintaining the same lifting height, effectively reduced the workshop height by over 1 meter, significantly lowering the overall investment. This adjustment saved the company approximately one million in the construction of the workshop.

Identify Whether You Are Dealing with the Manufacturer or the Supplier

Manufacturers and suppliers work in collaboration. The manufacturer’s role is to design and produce the crane, while the supplier is responsible for transportation, installation, commissioning, and subsequent maintenance services. Customers might wonder why manufacturers can’t handle these tasks. The reason is that it requires significant human and time resources. If suppliers handle these tasks, manufacturers can save time and improve their efficiency. If this is your first time purchasing a crane overseas and you lack experience, it is advisable to choose a supplier, as this will make the process much more hassle-free for you.

Customization and Personalization Options

Some overhead crane suppliers offer customization and personalization options, allowing adjustments and improvements based on your specific needs. Considering your work environment and workflow, choose a supplier that provides customized services to achieve a better working experience and results.

Safety Standards and Certifications

Safety is always the top priority. Ensure that the selected overhead crane complies with international and local safety standards and has the necessary certifications and licenses. This will reduce operational risks and protect the safety of your workers.

Comparing Quotations from Each Overhead Crane Supplier

Start by examining the brands of overhead cranes, electric hoists, and electrical motors. If there’s a significant difference in the brand quality between the overhead cranes, electric hoists, and motors, then the prices will likely vary greatly as well. This includes considerations for the quality of electrical motors.

Next, look at the materials, such as columns, load-bearing beams, and rails, which are all metal materials. First, check their specifications and sizes, and how many kilograms per meter they can bear. After reviewing this, inquire whether the materials meet bid or national standards. Even materials of the same specifications can have different weights depending on whether they meet bid or national standards. If the order quantity is large, the price difference can also be significant.

Examine the accessories. In some quotations, the proportion of items like conductor bars and rails can be substantial. However, these items are not within the overhead crane manufacturing company’s scope but are directly purchased by the business manager who signed the contract with you. Keep an eye on this aspect.

Lastly, be sure to clarify with the overhead crane supplier whether they are offering a used overhead crane or a new one. Second-hand overhead cranes will generally have a much lower price.

Choosing the Installation Team

For overhead crane installation, you can opt for a qualified overhead crane supplier that offers comprehensive services, including manufacturing, installation, and commissioning. Additionally, the chosen installation team must be a professional group with a special equipment installation safety certificate and the qualifications to handle the corresponding lifting capacity. The benefits of an experienced installation team are evident, such as preventing abnormal malfunctions during later use.

After-sales Service and Warranty

Choosing an overhead crane supplier that offers comprehensive after-sales service and long-term warranty is essential. Ensure they can promptly respond to your needs and provide professional maintenance and servicing to extend the lifespan of your overhead crane while reducing maintenance costs. If your overhead crane experiences downtime due to repairs or servicing, it can significantly impact production, resulting in indefinite financial losses, which can severely damage your business and decrease customer loyalty. The longer the wait for overhead crane operation, the worse the situation becomes. Therefore, if suitable repair services aren’t available locally, ensure your overhead crane supplier can effectively address this issue.

If repairs are not covered under warranty, the repair costs can be quite expensive. Please consult your overhead crane supplier to understand the duration and coverage of your new crane’s warranty.

- How long is your warranty period?

- Does it include labor, parts, and shipping?

- What is not covered?

- Is there a local service team available to handle warranty issues?

Finally, I would like to emphasize that purchasing an overhead crane is a significant decision that requires careful consideration and comprehensive evaluation. Through the considerations provided in this guide, I believe you will be able to make a wise choice and achieve a satisfactory purchasing experience with a good return on investment.

If you have any questions or need further assistance regarding the purchase of an overhead crane, please feel free to contact our professional team. Kuangshan Crane is committed to providing support and services to ensure your needs are met and success is achieved.