With the growing awareness of human environmental protection and the influence of green life policy, the upsurge of banning plastics has swept the world with a rapid trend, Therefore, green packaging that “use paper to replace plastic” has become the development trend of the world’s packaging industry. In particular, the demand for pulp molding tableware has become increasingly sought on the market. With their health and environmental protection properties, they have gradually replaced foam and plastic tableware products.

Pulp molding tableware

Pulp molding tableware, a kind of disposable paper tableware, is mainly made of plant fiber pulp and board, such as wood pulp, reed pulp, bagasse pulp, bamboo pulp, etc. It needs to be molded by the pulp molding process to obtain the final product. As the materials used in pulp molding tableware are harmless to the human body, they are loved by many people within the catering industry. Pulp molding tableware products not only have good performance but also have better product characteristics than foaming plastic tableware. As a matter of fact, they have a high value of recycling and good natural degradation performance.

The development trend of pulp molding tableware

Paper packaging is currently recognized as a green packaging, which has many advantages in energy and resource savings for environmental protection. In 2016, the global soft packaging market was about US $217 billion worth. By 2020, it is expected to reach over US $261 billion, showing a steady growth trend. Since pulp molding tableware are included in the green environmental protection products, they are widely concerned by countries around the world. Pulp molding tableware is a profound revolution in the food packaging industry, and it will gradually occupy the top position on the disposable tableware market.

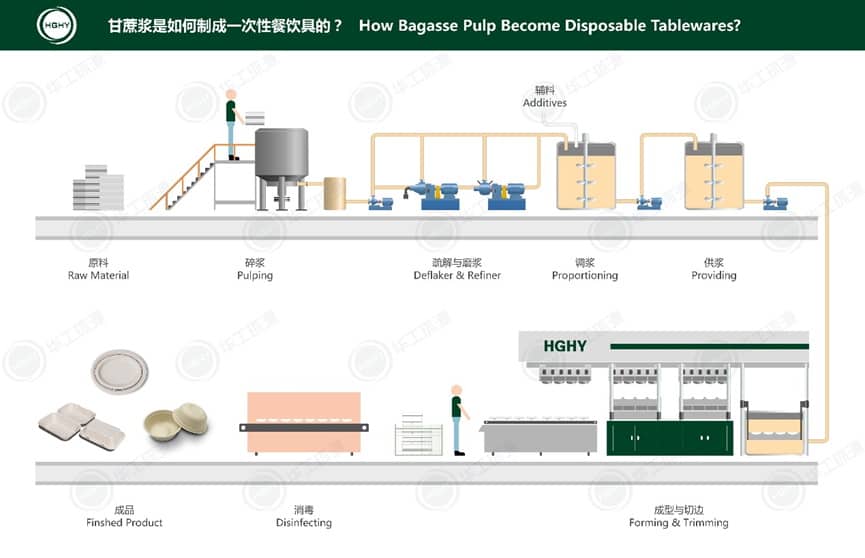

The production process of pulp molding tableware

Although the structure of pulp molding tableware looks simple, the technology applied in this process is quite sophisticated.

The production of pulp molding tableware is divided into five stages:

1) Pulping: soak the raw materials and put them into the hydraulic pulper for crushing. After screening, desanding, and refining, the raw materials are processed into the raw pulp. Then a certain amount of additives is added into the mixing tank to prepare the mixed slurry.

2) Forming: forming is the critical process of the pulp molding tableware production line. There are two main forming methods of pulp molding tableware: the injection extrusion molding inside the mold and the vacuum absorption molding outside the mold. Their principles are to make the pulp flow through the mesh mold to filter out the water, leave the fiber on the mold, and form the wet embryo in the semi-wet state.

3) Drying: in this process, the drying method of pulp molding tableware can be divided into two kinds. The vacuum absorption molding outside the mold mostly adopts drying channels and direct heat to dry the pulp in the mold. The injection extrusion molding inside the mold mainly heats and dries the pulp in the mold.

4) Edge cutting and sterilization: to ensure the beautiful appearance, stable size and shape, and smooth internal and external surfaces, the products need to be moved into the edge cutting machine to cut off the redundant edges.

In this process, the water content of the paper mold tableware need to be strictly controlled, which is generally 25% – 30%. However, due to the difficult control of the water content, a spray iron shaping mold is applied to moisten and heat the tableware to achieve the requirement of plastic.

Finally, the tableware is sterilized by ultraviolet according to the health requirements.

5) Packaging: the whole packaging process should ensure that the tableware is clean and sanitary.

Pulp molded machines

Pulp molded machine has become essential equipment due to the more and more technical personnel participating in pulp molding. In addition to the production of disposable pulp molding tableware, the pulp molded machine is also suitable for the manufacture of bagasse pulpboard, paper food box, high-grade industrial shockproof packaging, and other products. If you are considering installing pulp tableware machines, the pulp molded machinary from HGHY deserves to be included in your purchase list.

Pulp molded machine from HGHY adopts a fully automatic system, which can have flexible and accurate operativity. Because of its cost-effective intelligent apparatus, it can maximize your production efficiency. Its most outstanding feature is to use Siemens PROFINET communication mode to realize remote production monitoring and master production overview.

HGHY, with 20 years of experience in research, development, and manufacturing of pulp molding technology and equipment, has won the favor of many famous partners in the world. HGHY research team is formed by rich professional knowledge and young talents from renowned Chinese Universities. With the hope of this article can provide you with a better understanding of pulp molding tableware. HGHY will be your most satisfactory partner.