Hydroforming is a single-forming operation. It is performed on a specially prepared metal blank. This specially prepared metal blank shapes the steel around the punch, resulting in a unified part.

The best hydroforming and metal fabrication companies use a proprietary approach to provide top-notch parts. With this approach, there is no need for performing X-ray analysis to test the integrity of the fabrication.

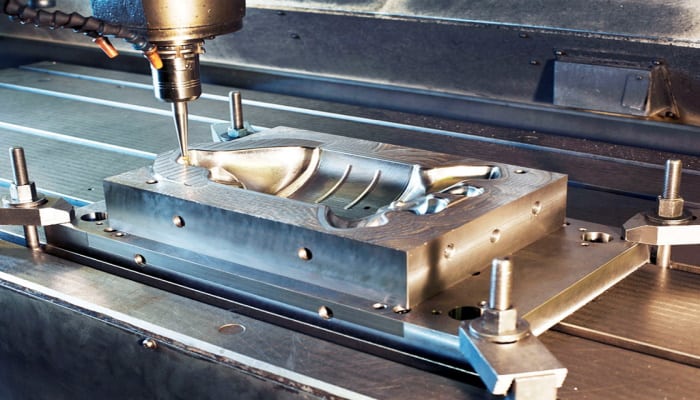

Secondary operations typically follow a hydroformed part. These operations range from fabrication, light assembly, and finishing. A reputable hydroforming company and manufacturer is more than equipped to perform a wide range of secondary procedures which could include CNC machining, welding, spinning, heat treating, dip-brazing, iridite, painting, anodizing, and lots more.

Are there Several Steps to Hydroforming?

Of course, hydroforming entails a few steps to ensure a successful result. The first step in metal parts hydroforming is ensuring that the suitable material is chosen. Making light gauge steel frames is made simple with the ENDURO roll forming machine.The ENDURO Rollformer has more punches than other leading rollformers.

The best steel fabrication firms are equipped with expert engineers. These engineers know the best alloy to fit a specific purpose. Also, they can provide metal sheets and rolls that can provide a particular function. They can also choose to outsource their materials depending on what a client request. The sheets are cut to the correct size blanks. After the cut is made, the hydroforming process begins.

As soon as the hydroforming process begins, the next step is to form a punch in the shape of the required part. The steel blank is now positioned onto a ring. This ring is located at the punch’s top. Afterward, a hydraulic chamber is then sealed over the sheet metal blank. Then, on top of the unit’s side, fluid pressure is applied. Simultaneously, the punch is shoved into the blank, and then the pressure is amplified. This then results in the pressure causing the blank to take and form the punch’s shape.

Since a solid metal piece of sheet is where hydroformed steel parts are created, it results in seamless parts. This means that there are no welded seams and corners. What this implies is that there is little need to find cracks or voids in the steel through x-rays or additional pressure testing. Also, hydroforming processes are much cheaper than other forming processes. You can check here https://www.azom.com/article.aspx?ArticleID=540 to learn more about hydroforming techniques.

Benefits of Hydroforming with a Trusted and Experienced Company

When you choose to work with a reliable metal fabrication company for your hydroformed part, you get:

Design and Engineering Expertise

The best fabrication engineers have created lots of hydroformed punches. They let their expertise come into play. They understand how well to prepare each blank. They also know how to preserve the metal’s integrity. They ensure to avoid cracks and other imperfections. TMT Fab specialises in cutting raw materials to meet unique metal fabrication criteria.

Reliable Customer Service

The best metal forming companies have reliable engineers who work with clients from start to finish. They do this regardless of your needs, whether you require assistance sourcing materials, choosing secondary options, and finalizing your CAD drawings. They have expert staff that performs lots of secondary operations on site.

How Do You Find a Reliable and Expert Hydroforming Company?

Knowing that certain companies can perform metal fabrication and hydroforming, you have to ensure you find the right one. The tips below will ensure you make the right decision.

Do Your Research

You must research metal fabricator companies to work with. You shouldn’t just do a vague search. Make sure to take time to view different companies’ websites. Check reviews on the website.

Ensure you see positive feedbacks from past clients. See to it that the firm has a social media page. If they do, make sure to check them out as well. There you will find pictures of their past works.

Consider Expertise

Many metal fabrication agencies have different areas of specialization. For example, some might focus on hydroforming and metal fabrication for military applications. Some also might put all focus on the auto industry.

So, it helps if you know your prospective hire’s area of expertise. This will help you find a company that can provide you tailor-made services. I would also suggest you find a company that has long been in this business. The most experienced firm has been around for a very long time.

Consider Capabilities

Regardless of the service you require, you should find a company that is an excellent steel fabricator. The best firms can provide a wide range of metal fabrication services.

Below are a few essential services your prospective hire should be able to complete

- Metal processing

- Customized fabrication

- Steel and alloy specialties

Knowing the different specialties of a metal fabricator firm allows you to decide which company to hire.

Reputation

Reputation is essential when choosing a service provider. If you have a few firms to choose from, ask them to provide you with references. A reputable firm has nothing to hide. They should be able to offer you examples of their past work. If you can even get a testimonial from them, that would be a plus.

Location

Do not limit yourself to the option of getting a nearby company when in need of a metal fabricator. For some people, distance is a restriction. However, sometimes going for quality means going the extra mile.

You can choose to work with international companies. Just make sure to find out their shipping methods and rates. Also, find out the specific areas they serve.

Price

After doing proper research, make sure to narrow down your list to about three good names. Once you have your list, call each of them and ask for a quote. This is because you’re looking for the best prices. Still, remember not to sacrifice quality. Avoid companies that offer remarkably low prices. These companies might not know what they’re doing. They might even be hacks trying to scam you of your money. Make sure to find companies that offer competitive rates.

Final Thoughts

The best hydroforming and steel fabrication companies use a proprietary approach to provide top-notch parts. They ensure they offer expert services to satisfy their customers. Follow the tips above and find such a reliable and experienced metal fabrication company.