A cooling system contributes vital role in working of thermal power station that rejects heat to the atmosphere by cooling of a water stream to a lower usable level of temperature.

The towers vary in size from tiny to giant which will be up to two hundred meters tall and one hundred meters in diameter. Smaller towers are ordinarily factory-built, whereas larger ones are created on site.

Primary purpose of cooling tower is to raise down the temperature of water which is coming from condenser unit of power plant. It is advisable to use water temperature sensor as well to control the temperature of water.

How Do Cooling Towers Work in Power Plant:

- In thermal power plant, water is heated in a boiler to make steam.

- Steam then goes to the turbine unit. After that, the steam turbine engine rotates with the flow energy of steam.

- Steam utilizes its heat and flow energy to convert into rotary power of turbine during this process temperature and pressure of steam drops

- This steam is then exhausted out of the rotary engine and needs to be cooled to convert it in to liquid part.

- For this modification of part to require place, cooling water is employed during a instrumentation referred to as Condenser.

- In condenser, cooling water is circulated through tube and steam passes on the surface steam losses rest of its heat by giving up to water and condense back to water .

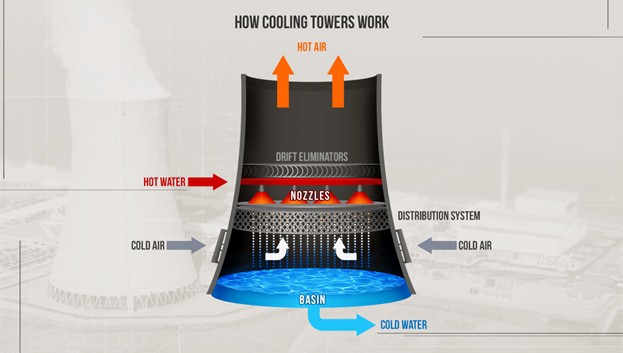

- Here the cooling towers serve their purpose, water coming out from condenser unit is brought to cooling tower and air is passed through the tower

- Both streamline are passed through normally in counter direction

- When they came in contact water temperature raise down back to reusable level for condenser

- Some water also evaporates during cooling and make up water is added to fulfil this requirement.

- That’s how continuous cycle of water flow from condenser to cooling tower, raise down in temperature and back for condensing to cooling tower keeps in flow undisturbed.

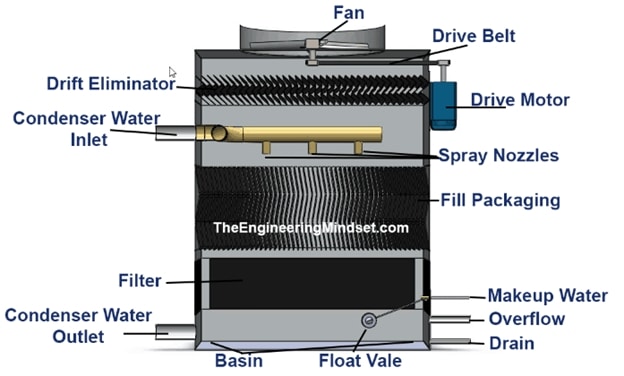

Some major components of cooling tower you should know are:

Cooling tower consist of many components as such as

1. Cooling tower packing

You should know Cooling tower packing is one among the foremost vital elements of a cooling. The packing ensures most contact between air and water to modify cooling and has been discussed above

2. Drift separators or Eliminators

A drift agent is meant to capture massive water droplets caught within the air stream, and stop the droplets and mist from escaping the cooling. Over time, however, the drift agent will wear out and become brittle, or perhaps become clogged if no correct preventative maintenance set up is enforced. Drift is water lost from cooling towers as liquid droplets are entrained in the exhaust air

In each cooling there’s some removal of water into surroundings as evaporation occurs. This loss is typically within the kind of pure water vapor, possessing no harm to the setting.

Some types of drift eliminator are

. Standard Drift Eliminators

Standard drift eliminators are made to compensate the loss of water, chemicals etc in form of droplets that evaporate into the atmosphere during a cooling by capturing and preventing the harmful droplets from exiting the cooling tower and into the setting.

. Drift Eliminators

Drift eliminators perform their operate by inflicting droplets to change direction and lose their rate once they hit the blade walls causing the droplets to fall into the cooling system. the foremost economical cooling system drift eliminators can keep your loss of drift to not up to a .005% drift rate.

. Cellular Drift Eliminators

Cellular cooling drift eliminators offer the foremost impact quantity of expanse for max potency and removal of drift. The cellular style of this agent permits for higher flexibility once putting in and trimming elements for the right work. an element that’s important regarding drift emissions of cooling towers.

. Blade Drift Eliminators

Blade cooling drift eliminators afford rugged sturdiness and a protracted era thanks to their significant gauge blades. These eliminators are made to be value effective whereas providing adequate droplet capture to stay your method water in your cooling

3. Gear and fans

All components of a cooling system are necessary, however it’s definitely necessary to exercise the required care of the drive gear of your cooling system, these being the turning components of a cooling system

4. Water distribution system

For Engineering sectors, installation or production of open and closed water distribution systems for your cooling system, as well as the suitable nozzles.

5. Air intake louvers

Air intake louvers prevent water splashes from the water assortment tank and forestall larger dust from incoming within the storage tank.

6. Other tower elements:

Thermostats, Protective grille, frost protection level probes, access hatches, , water treatment installations etc depending upon uses .

Conclusion:

- We have discussed in detail how a power plant works and function of cooling tower in it with you.

- Then you got the idea of different parts of Cooling tower and their individual functions

- In short cooling tower cools down processed water coming from condenser and provide cooled water back to condenser so condensation of steam to water keeps flowing without disturbance.

- Forced Draft has is more efficient than natural draft however initial cost and operating budget are high but it deliver more better results

- Cooling tower size capacity depends upon how much decrease in temperature you want to acquire for your power plant

- Cooling is consider cheap source of water cooling treatment on large industrial scale rather than utilizing costly Chillers or other system which is also not environmental friendly

- Normally water that flows condenser to cooling tower is canal water as a natural and cheap solution