If you are looking for a company that can produce complex medical applications, you will need to find an experienced medical converter that can produce all of these products for you. There converting capabilities of these businesses should include the ability to produce wound care products, surgical products, and medical disposables. They should also be able to make complex medical device components and have additional converting capabilities that will allow them to make virtually any type of medical product that you need. Here is a range of different converting capabilities that these companies will have, and the complex medical applications that they can produce.

What Will These Converting Capabilities Include?

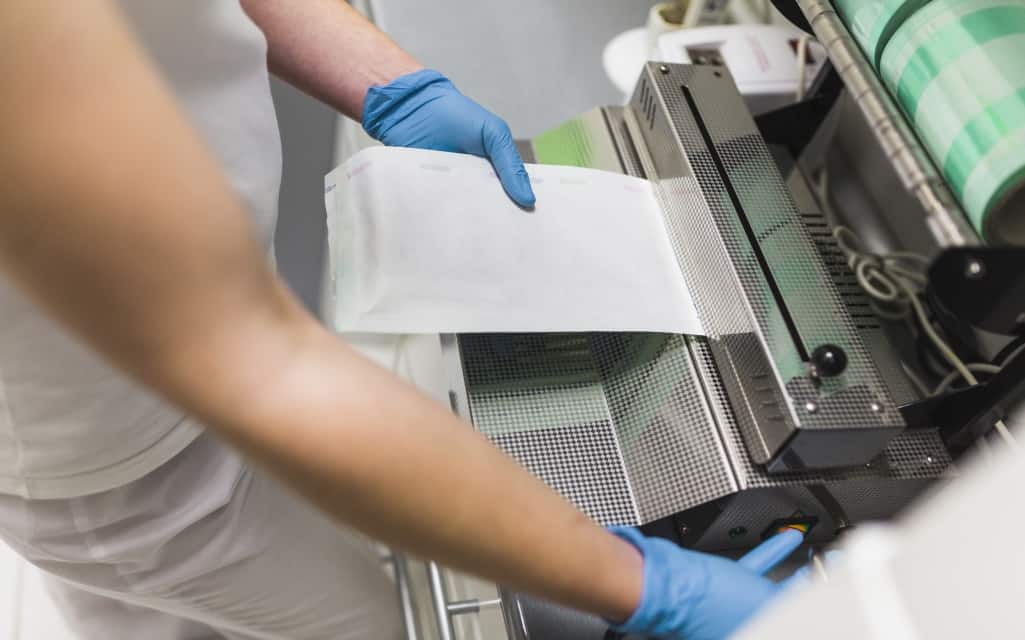

These businesses will likely use precision rotary die cutting machines that can produce different products with high precision and speed. They will also have at their disposal automated laser systems, ones that are perfectly calibrated for seaming, perforating, cutting, marking, welding, engraving, and etching. Laser drilling is another option that they may have available, a technique that is important when you are having multiple holes that must be at specific diameters. They should also be able to do laminating jobs, including those that will involve multiple layers. Custom rewinding and slitting procedures should also be within their wide range of capabilities. In addition to this, waterjet cutting, specifically for different types of foam, will also be available to you. Ultrasonic welding, such as for antimicrobial packaging, should be on the list of the capabilities that these businesses have available.

What Type Of Materials And Adhesives Can They Typically Provide?

These companies should be able to produce a wide range of medical materials that are commonly used with these businesses. For example, they may create composite wound care dressings, diagnostic test strips, carrier frames, and lateral flow test strips as well. Medical foam tape, diagnostic disposables and different types of adhesive tape will also be possible. Multilayer island dressings, and hydrogel dressings, are just a few other products that they will be able to produce for your medical facility. These are just some of the many products they will be able to produce. The most competent businesses will do all of these flawlessly each time. You will need to do some research to find a business that can meet your demands, but also save you money as a produce these products for you.

How Do You Find The Best Companies That Can Produce These Products?

Although there are many businesses that do offer these services, only a few of them will be able to produce everything that you want. You also need to consider the precision by which they are able to make these products, and the cost of doing so. When you do research on these businesses, start to look for testimonials that they may have received from other medical practices. Additionally, get estimates from each of the companies that you find so that you can have a rough idea of how much they are charging for these products that they will produce for you. Almost all of these will be accessible on the Internet. You can go through their website. They should have their services prominently displayed. If the website is organized properly, you can drill down to the types of services that you are looking for. From laser drilling to waterjet cutting, they should be able to accomplish all of this and more.

Other Ways To Evaluate These Companies

If you want to evaluate these companies, you ought to start with how long they have been in business. Check the Better Business Bureau, and see if there are any complaints that have been filed against these companies. Next, you will take into account the comments that you find online about these businesses, and finally look at the prices that they charge. The most comprehensive companies those that are offering to do this for a reasonable cost, will be top contenders for your business. In some cases, you may have to work with a couple different businesses at once. Not all of them are going to be able to do medical converting for every product that you need. However, you do your research properly, you should be able to find a business that will cater to every request that you have, producing excellent products at a reasonable cost. Finally, you must consider the facilities where these products will be made. They ought to use climate controlled rooms that are completely clean. They need to be a large material supplier network, one that is recognized as an industry leader, offering the best and most cost effective services for fabrication and the production of flexible materials.

How To Finally Choose The Best Company

This evaluation process will not take very long at all. You will quickly find medical converting companies that do offer all of these services. Your job is to choose the best one, which means they are not only cost effective, but they are also the most comprehensive business the industry. Some of these businesses might be near you, whereas others might be quite a distance away. It’s always possible to have everything shipped. You need to make sure that this business is capable of handling your order effectively and efficiently, for prices that will keep you coming back to them. Once you make your choice, you will always be confident that every product that you order will be created with the highest level of expertise.

In conclusion, if you do need to find a business with a wide range of converting capabilities, specifically for complex medical applications, you now know how to find the companies. Your evaluation of them will help you provide the best medical products for your patients, and also save money by working with this affordable business. It is so important to always have the best products for your clients, yet also save as much money as possible. These tips should lead you to the best business that can offer you all of these services, plus help you save money when we stocking your company with all of these medical related items.