Most of the industrial sectors, especially factory outlets need a huge amount of stainless steel. As this is a rust-free and corrosion resistant material, stainless steel is used for manufacturing different structures and spare parts. Most of the time, the buyers ask for a metallic sheet which is then cut and designed into perfect shape. Majority of people are not aware of the high quality metal cutting services. There are some important types available in metal cutting services. Both conventional and modernized tools are being used for the same service.

More about metal fabrication

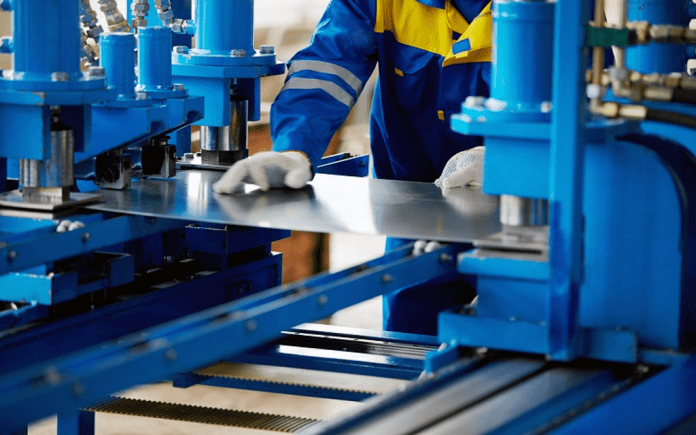

The high quality metal cutting services are mostly used in metal fabrication. This is a procedure used for building metal structures by bending, cutting and assembling large sheets of stainless steel. It is used for constructing machines and structures using different types of raw materials. This job is currently undertaken by a fab shop and the work starts on the basis of engineer’s drawings. If the drawings are approved, the contractor will start constructing the product.

Get hold of Common Types

Depending on the flexibility of clients and their requirements, there are various types of high quality metal cutting services available these days. Now, customers can choose from various kinds of metal cutting solutions, which help in matching up with various shapes and sizes of metal sheets.

Different Forms and Procedures Revolving Around High-Quality Metal Cutting Services

Plasma cutting is widely used in many industries, and it accounts for a good percentage of metal applications out there. A plasma cutter uses a torch to pass high-velocity gas that creates intense heat to cut through metals. The process involves high speed and precision cuts, which makes it popular in CNC applications as well as hobbyist shops. Additionally, it produces a smooth cut edge as a laser, and it does not produce metal chips. However, plasma cutting is only used to cut metals, unlike laser cutting, that can be used to cut through many types of material.

- Turning is a common procedure if you have ever worked with wood on a lathe. Here, the metallic sheet is placed into a big turning machine which spins fast. There is a cutting tool used for removing the top layer of metallic sheet in order to give it the desired look.

- Drilling is one of the common metal cutting services. There are some times, when you have to hold metal sheets and other similar parts together with fasteners and screws. For that, a hardened drill is used for cutting a hole of required sizes.

- When you are working with any steel material, you might come across blemishes and little metallic burls at the cut ends. It is important to clean up these blemishes or else accidents can take place anytime. For ensuring user safety, a grinder is used. This Grinder mainly uses the abrasive wheel for wearing the metal down and gives it a reflective, sharp and clear shine.

- Welding is considered as one of the most common techniques, used for cutting or joining metal pieces. For that, the experts need to work on higher temperature levels around 3500-degree centigrade.

- Basic cutting is what every expert can offer. It primarily starts with three hand tools. There are reinforced teeth of a hacksaw which helps in short cutting the procedure. For removing all the unwanted metal bits and pieces, chisels are used. These metallic bits are forced into heated metal with the help of an anvil. Craftsmen further use shears to cut aluminum and steel sheets.

- If you are looking for modernized ways of cutting sheets, you can opt for laser cutting. This is primarily a fantastic tool for those jobs where you are in need of accurate measurements. Here, a concentrated beam light is used for cutting through the metal. It helps in providing a clean cut in some of the complex patterns.

These are some of the methods relating to high quality metal cutting services. No matter, whichever method you choose, it is important for you to get help from the experts and professionals. Once you have the right help and guidance available, you can then use these sheets for any industrial use.