Electrical safety at the workplace is a crucial and no potential hazard situation should ever be overlooked. Electric workers working under such scenarios are always under the threat of getting an electric shock or an arc flash or an arc blast, which can lead to death or a severe injury. As a workplace owner, you must acknowledge the failure in the electric circuit, which can cause death.

Additionally, it is your duty to impart proper training to the workers for safeguarding themselves and avoid being at risk. You need to make sure that only high-quality supplies are bought from the electrical supplies so that there are no chances of any dysfunctionality in the circuit and further at the job site.

They are the ones who would continuously be in touch with the light source, electric equipment, machinery, tools, etc. If they are trained well, they can save thousands of lives.

Due diligence by the workers is expected by the Canada federation to protect themselves from any electric hazard. Most of the casualties or any incidents are caused when the worker is in direct contact with power lines, or high-end machinery tools or due to inadequate knowledge about handling electricity and metallic objects together. In this content piece, we will discuss some of the checklist points for avoiding the electric dangers at the workplace.

Everyone, including electrical engineers, electricians and the overhead line workers, are at risk because they are the ones who are constantly exposed to the circuit areas. Workers perform the task of installations, repairs of the machines and also fix the light fixtures. Any potential mistake during the inspections of the same, if missed, can lead to death. Here are a few tips to mitigate the electric hazards on the site.

1. Check the overhead power lines:

These power lines carry high voltages that are required to keep the machinery working. The high voltage can cause severe burns and electrocution when workers are exposed to it without any safety measures. They need to keep a safe distance, say a minimum of 10 feet from the power lines at the workplace.

Additionally, safety sign boards and precautions should be mentioned frequently at the worksite. You can also train them and ask them to ensure that nothing is stored under the power lines.

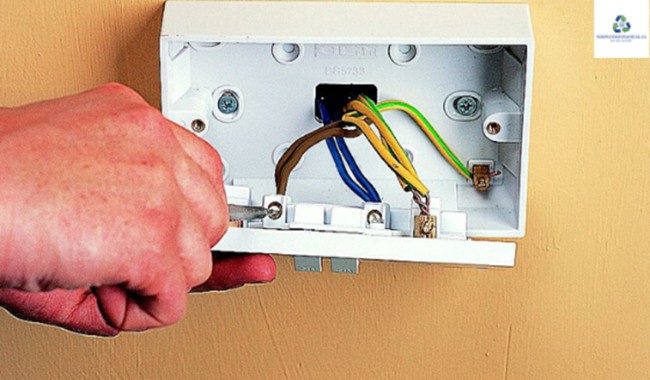

2. Damaged Wiring and circuits:

Buying electric supplies from the lighting stores, Canada ensures that high-quality wires are installed at the worksite. Inadequate wiring can cause overheating or even fire at the site. Hence it is required to place correct wiring type that can bear the electric load and causes no breakdown.

No outlet of the circuit should be left open, and the circuit breakers should be efficiently installed. It is also required for you to perform a fire risk assessment to identify the risk areas or bad wiring.

3. Defaced Tools and equipment:

Any damaged electric equipment is highly dangerous. Hence, train the workers on-site to maintain or repair the wires if found unusual. Ask them to perform regular checking of the circuits and deformities in the cables and wires. Inform them to replace any such damaged wires or defective equipment present on the site.

Don’t overload the circuit beyond its set limits. Additionally, train them to perform Lock Out Tag Out(LOTO) before starting the maintenance work at the site.

4. Improper grounding:

Proper grounding is the first step towards ensuring that no hazards occur on the electric site. Many worksites frequently violated OSHA safety laws when it comes to improper grounding. The plates, light fixtures etc. should be properly grounded at 0 volts to avoid any potential hazard at the site.

Why? Because, if you avoid the grounding, the electric flow makes these parts energized, which then becomes responsible for the electrocution. The metallic pins should never be removed because it sends back the unwanted voltage back to the ground. There is no room left for the unwanted voltage to pass through the circuit and thereby, the risk of electric shock is mitigated.

5. Damped Areas:

The environment around the electric equipment also plays a major role in safeguarding the workers at the site. We all know that no electrical equipment should be handled with damp hands or cloth.

The same ideology applies to the placement of electric appliances, they should not be placed in wet locations because such locations increase the chances of electric shock. Also, during the maintenance or repair work, a qualified electrical worker should check that the electric equipment is dry and not operated in wet conditions.

6. Open and exposed electric parts:

Exposed parts mean the workman can easily access or be in contact with the energized electrical conductor or circuit part. These detached parts are responsible for potential shocks and burns. Therefore, train the team to ensure proper guarding of the wires and equipment, and if any damage found, replace them instantly.

Few other things to take care while handling electric circuits and equipments are:

- Everyone has to make sure that the safety laws are diligently followed and no electric device is tampered by the team member;

- During the regular checks, ensure that defective cord or plug is replaced as soon as possible;

- Purchase electric supplies from the reputed lighting stores Canada, which as an emergency shut off switch;

- Heavy load equipment should have enough space around it for easy and proper handling of the same;

- The electric workers should not wear any metal accessories or jewellery during the operation of the electric appliance.

- Train workers to ensure that the electrical machinery is de-energized before the operation.

- Ensure that the team wears personal protective equipment while working on the sites.

We wish that no hazards occur at the workplace, and we create a healthy and safe working environment for the electric workers. For any help and suggestion, you can always call an expert and take guidance.