Health is wealth is a phrase that has proved to be true with the outbreak of the global COVID-19 pandemic. It brought with it a lot of uncertainty, unwanted changes, fear, and anxiety. All this has lead to a sudden increase in the demand for advancements in the healthcare industry globally.

Many innovations took place when demand for medical equipment increased. With the increasing demand for oxygen, different types of oxygen molecular sieve were manufactured by reputed manufactures to generate medical oxygen.

Medical science has seen massive growth in the past few years. Now you have a solution to even those problems that seem impossible to cure a decade ago. Be it surgical instruments, dental instruments, diabetic or cardiovascular devices, the new techniques have increased their efficiency without a doubt.

What Are The Different Types Of Medical Equipment’s?

Medical equipment is of various types based on for what purpose they are being used. There are majorly five types of medical equipment. They are:

- Diagnostic Equipment: These types of equipment are used for diagnosing the patient’s condition. It includes a stethoscope, X-Ray machines, CT scans, MRI scans, etc.

- Laboratory Equipment: These pieces of equipment are solely used in the laboratory. It includes equipment required for blood collection, drug testing, and analyzing other biological materials like urine.

- Durable Equipment: These types of medical equipment are used when prescribed by your doctor. It includes wheelchairs, hospital beds, ventilators, oxygen concentrators, etc.

- Treatment Equipment: This type of medical equipment includes medical lasers, infusion pumps, etc. They are used to treat certain medical conditions.

- Life Support Equipment: These medical equipment are used in conditions when it is about life or death. It includes Incubators, ventilators, dialysis machines, etc.

5 Different Techniques Used In Making Medical Equipment’s

1. 3D Imaging

The first technique that is used in medical manufacturing is 3D Imaging. It gives you a 360-degree view of an object. You can have a detailed view that leads to precision in manufacturing. This technique was developed in the early 1990s. Since then this technique is getting better and better.

Today, 3D imaging is not just used in the manufacturing of medical equipment. It is also used by dentists and dermatologists. While manufacturing implants and prosthetics this technique do wonders with its abilities. It is because it has the following advantages:

- It gives you a detailed and complete overview.

- You can see the object from different perspectives.

- It can reach areas where the human eye cannot.

- It provides you a reliable diagnosis.

- It helps you to understand the problem better.

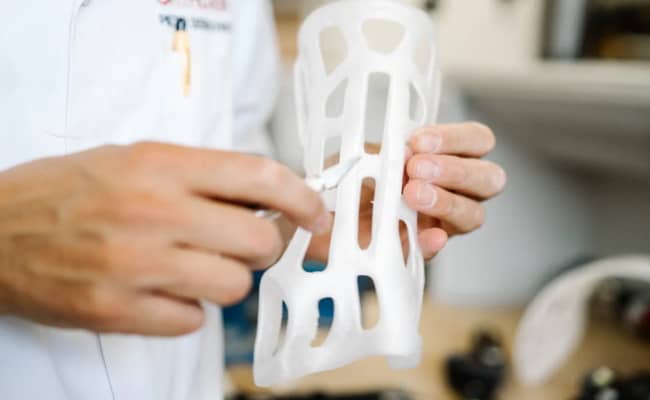

2. Additive Manufacturing

The second technique is Additive manufacturing. It is also known as 3D printing. It is a technique that manufactures a part very minutely and precisely with the help of a laser. It is capable of manufacturing complex structures that cannot be manufactured using molding.

Additive Manufacturing is used with 3D Imaging. Thus, it reduces the time taken for manufacturing medical devices. This technique is best suited for making surgical implants.

The designs are made digitally using computer-aided design software. Then they are cut with the help of a laser. Because of this, additive manufacturing helps in manufacturing customized medical equipment and changes can be made at the last minute.

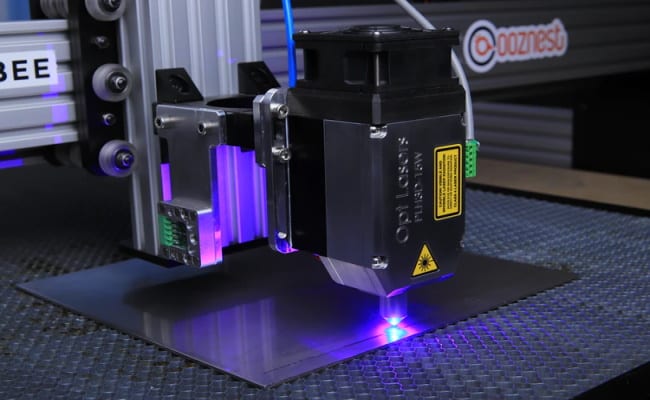

3. Laser

Laser technique includes a light beam that cut, marks or weld an object with great precision. They are flexible and highly accurate. It can cut the material in a width smaller than that of the diameter of human hair. It is not possible with a naked human eye. Using this technique high-quality laser therapy products can be manufactured.

There are several methods of laser technique:

- Fusion Cutting

It is a traditional method of laser cutting. It works with most of the metals. This method of laser technique has high precision and flexibility. It gives you clean cutting edges and on top of it, it is contact-free.

- Athermal Cutting

Another laser technique is Athermal Cutting. It is suitable for metals, polymers, and glass. The best thing about this method is that it has no heat effect.

- Laser Marking

Laser Marking can be used with metals and non-metals. This laser technique is fast and flexible.

- Laser Welding

Another method of laser technique is called Laser Welding. It works with metals and is precise and contact-free.

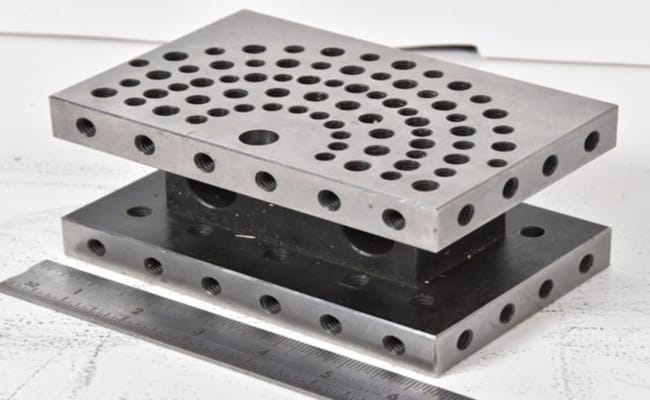

4. Machining

Machining in simple terms is a process that involves cutting material from a solid block for manufacturing. In medical manufacturing, it is important to get it done perfectly in the first go. You cannot take any chance because it is matter of life and death. Therefore, machining is required to cut medical grade material to manufacture medical equipment.

In this process, the complete design is made on computer-aided software. Then it was converted into a code that gives instructions to the cutting tool. Then finally it was cut with precision and you get the finished piece. But it needs to be as per the standards of the International Standards Organization.

5. Micromanufacturing

Micromanufacturing is a medical manufacturing technique through which smaller size medical equipment can be made. These devices are small in size but they have larger capabilities. They can be easily implanted in sensitive areas of the human body like the brain.

Micromanufacturing includes two other processes:

- Micromachining

It involves the use of micromechanical tools that have defined cutting edges. It helps in cutting parts of small medical devices with precision. It is impossible to do that with a naked human eye.

- Micro-molding

It helps in achieving the required size and dimension of the medical equipment that is being manufactured. It is highly efficient and cost-effective.

Conclusion

With the growth of medical science, medical manufacturing has achieved great heights. The techniques used are improving day-by-day which in turn improves the quality of manufactured products. Now you can get equipment made with great precision as per the patient’s need. What more you can ask for?